“RACING IS LIFE. ANYTHING BEFORE OR AFTER IS JUST WAITING” (Steve McQueen)

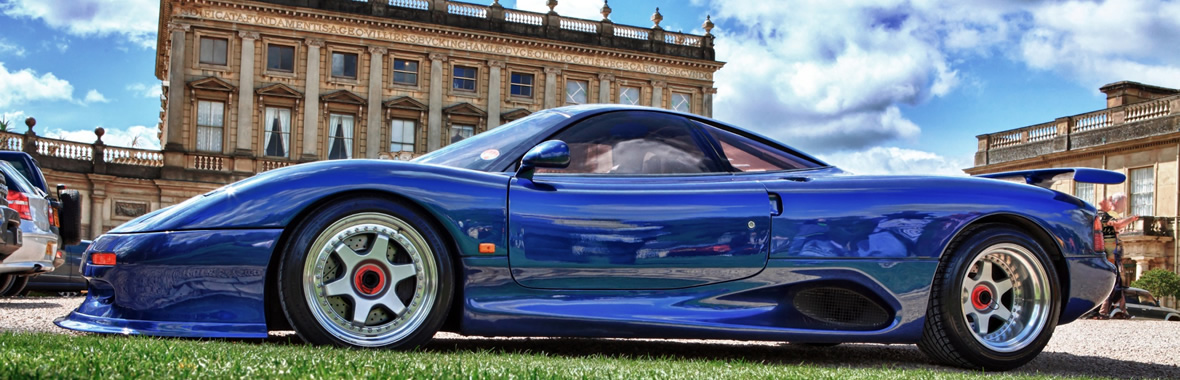

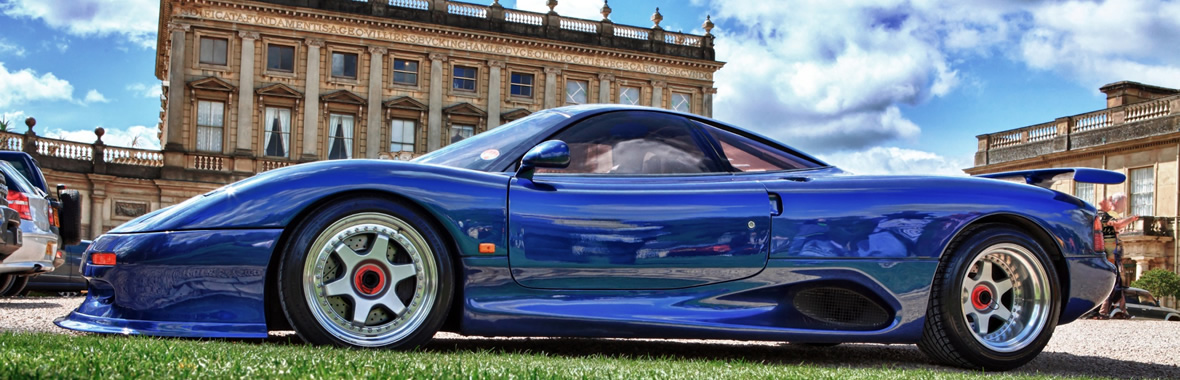

Working For Leading Motorsport Organisations & Progressive Industrial Brands (Inc. The Mobility And Efficiency Sectors) On: Race Cars, Hypercars, Luxury One-Off And Limited-Run Design Commissions, & Production-Validated Designs For Engines And Chassis Infrastructures.

Not public facing, instead choosing discretion and strict adherence to confidentiality agreements to support our clients. Meaningful relationships with manufacturers in Europe, Asia, and the USA, provides them with an extension to their own design facilities. As technical partner to the brands we collaborate with, we deliver performance-centric designs to keep them in front.

ORIGINS OF PARALLEL MOTION CONSULTANTS

Parallel Motion Consultants, a quintessentially British design house based in the heart of England. This is the outline of how three unique stories intertwined to create one industry-renowned F1™ brand:-

SPARSHOTT ENGINEERING

‘Chassis & Suspension Specialist’

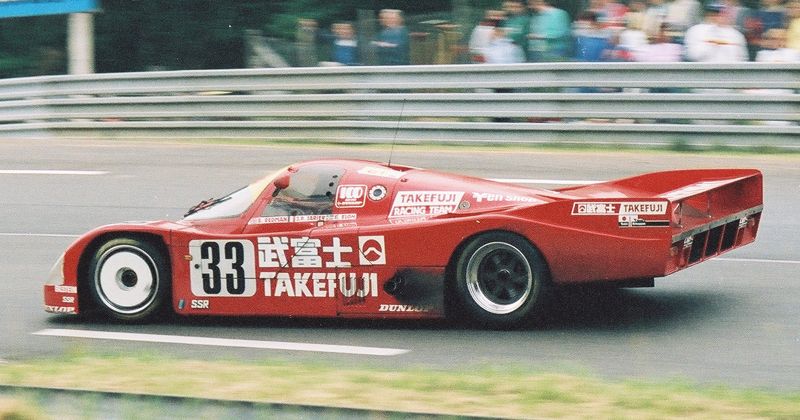

As Experienced Automotive F1™ Engineers, Much Of Sparshott’s History Is In F1™ Racing Cars, Indy, And Rally Cars, Namely Lotus, McLaren, And Ferrari. An Engineering Company Specialising In Fabrications For F1 & Indy Teams.

A leading sub-contractor to the racing industry, manufacturing complete cars and components for teams. Efficient dynamics means ‘lighter is faster’.

Headed in 1980 by technical director, Robert Sparshott – 1960’s Lotus F1 engineer/technician (Jim Clark), Indy 500 engineer winner, 1970s McLaren F1 privateer (debuted Nelson Piquet), 1970s McLaren sportscar partner constructor, BMW M1 Procar Championship (constructor for BMW factory team), Chaparral 2K Indycar constructor, 1985 F3000 Champion team owner, F1™ chassis and suspension specialist.

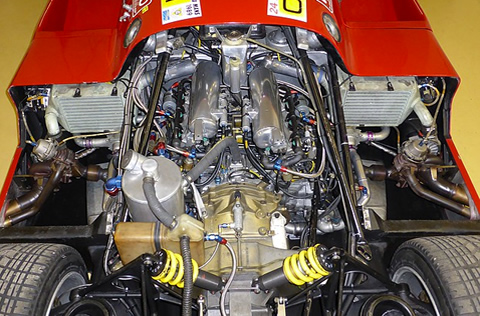

Sparshott Engineering > Customer base ranging from prototype and development projects to component parts for racing/competition cars in elite metarials. From electronic chassis and enclosures, to stainless steel work for many industries e.g. Aerospace.

Production of fabricated suspension components. CNC machines parts from Billet. Specialty in high precision fabrication work, involving the higher grade materials, such as Titanium, alloy steel, 4130 etc. Offering a design facility on special purpose machines and equipment enabling handling of a complete project package of design, manufacture, build and installation.

Workforce possessing a high level of technical skill and experience allowing great flexibility.

Created by Robert ‘Bob’ Sparshott, originally based in Milton Keynes near to the Tickford Aston Martin facility.

Bought out by engineering corporate in 2000 and amalgamated with Parallel Motion, latterly branded E-Squared Engineering, and moved into Parallel Motion HQ, Bicester Oxon, as a technical partner.

PEDIGREE

PEDIGREE HIGHLIGHTS

HIGHLIGHTS TIMELINE

TIMELINE LEGACY

LEGACY LEGENDS

LEGENDS THE NAME

THE NAME Phase PA – F1™

Phase PA – F1™ Phase CS – LE MANS

Phase CS – LE MANS Phase OR – Hypercar

Phase OR – Hypercar INCONEL

INCONEL CARBON FIBRE

CARBON FIBRE STAINLESS STEEL

STAINLESS STEEL TITANIUM

TITANIUM ALUMINIUM

ALUMINIUM THERMAL BARRIERS

THERMAL BARRIERS PRESS

PRESS CONTACTS

CONTACTS PHILOSOPHY

PHILOSOPHY