INCONEL : VICTORY

Inconel 625’s Ability To Resist Heat And Maintain Its Properties And Strength In Volatile, Harsh And Unstable Temperature Extremes Makes It The Ultimate Material For Engine Component Systems.

PARALLEL MOTION components, where supplied in thin wall stainless steel, can also be supplied in ultra-lightweight Inconel 625. Inconel 625 is a non-magnetic, corrosion and oxidation-resistant, nickel based alloy.

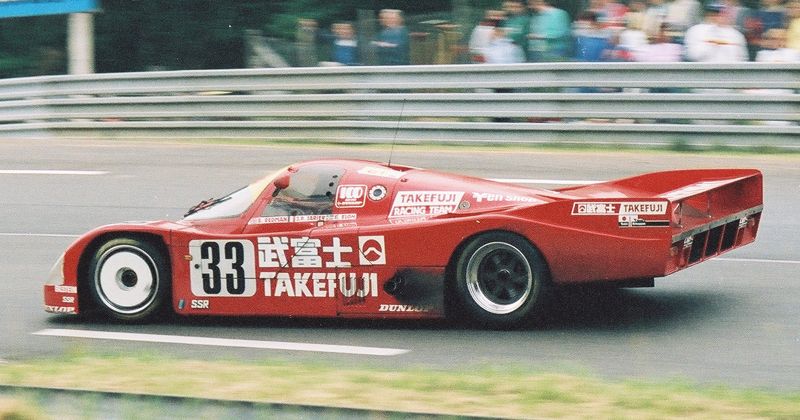

The main attractions of Inconel 625 to the Formula One™ & Le Mans arenas is in its extremely high tensile strength, with extreme thermo-chemical stability. The mechanical properties of Inconel allow comparatively thinner sections to be used than with other materials, thus reducing weight without compromising strength. Inconel allows for reduced thickness over traditional stainless steel, while strength is actually increased compared to identical amounts of stainless steel.

Racecar Performance – a typical Inconel 625 engine system manifolds set can be lifted with one’s finger tips alone, while matching the strength of a heavier stainless steel equivalent. Inconel’s incredible strength to weight ratio (similar to Titanium) allows very thin wall material to be used in construction, without risk to structural integrity. This combination results in incredibly light weight components that will not weaken over time.

Inconel alloys are oxidation and corrosion resistant materials well suited for service in extreme environments subjected to pressure and heat. This, combined with good tensile, fatigue, creep, and rupture strength, has resulted in its use in a range of testing applications (liquid fuelled rockets, metal parts for aircraft, aerospace, etc.) with the passage of time.

Touringcar Efficiency – In vehicular terms: Importantly the weight typically comes off the front or rear of the car and so has a profound benefit to the balance and all aspects of performance. These components are as close to a Formula One™ system that exists. Utilising type 625 Inconel in 0.4mm>0.9mm thickness for tube, silencer casing, & muffler internals typically, and 8mm>10mm Inconel for flexible bellows, brackets and flanges typically. (N.B. When some manufacturers extol certain high performance components as Inconel or Titanium, it may in fact typically be a mix of materials).

PEDIGREE

PEDIGREE HIGHLIGHTS

HIGHLIGHTS TIMELINE

TIMELINE LEGACY

LEGACY LEGENDS

LEGENDS THE NAME

THE NAME Phase PA – F1™

Phase PA – F1™ Phase CS – LE MANS

Phase CS – LE MANS Phase OR – Hypercar

Phase OR – Hypercar INCONEL

INCONEL CARBON FIBRE

CARBON FIBRE STAINLESS STEEL

STAINLESS STEEL TITANIUM

TITANIUM ALUMINIUM

ALUMINIUM THERMAL BARRIERS

THERMAL BARRIERS PRESS

PRESS CONTACTS

CONTACTS PHILOSOPHY

PHILOSOPHY