DURABILITY

Special High-Chromium And Nickel-Alloyed Grades Resist Scaling, Corrosion And Oxidation, And Retain Strength At High Temperatures. Stainless steel Is Used Extensively In Heat Exchangers, Super-Heaters, And Main Steam Lines As Well As Aircraft And Aerospace Applications Because Of Its Excellent Resistance To High Temperatures.

Sustainability – Additionally, the austenitic microstructure of the 300 series allows the steel to easily withstand and perform in temperatures well below freezing. The unique surface of stainless steel has no pores or cracks to harbour dirt, grime or rust. Stainless steel may be more expensive initially, but the extra value is offset by the durability and longevity of the steel, and significant cost savings are achieved in the long run. Therefore, when the total life cycle costs are considered, stainless steel can be a cost effective option.

Longevity – Stainless steel does not “rust” as you think of regular steel rusting – with a red oxide on the surface that flakes off. If you see red rust, or ‘scaling’, it is likely due to some iron particles that have contaminated the surface of the stainless steel and it is in fact these iron particles that are rusting. If the iron is embedded in the surface it is easily removed by gently applying pressure via a mildly abrasive material. Afterwards, stainless steel generally displays its original finish. Stainless steels typically require little or no maintenance.

PEDIGREE

PEDIGREE HIGHLIGHTS

HIGHLIGHTS TIMELINE

TIMELINE LEGACY

LEGACY LEGENDS

LEGENDS THE NAME

THE NAME Phase PA – F1™

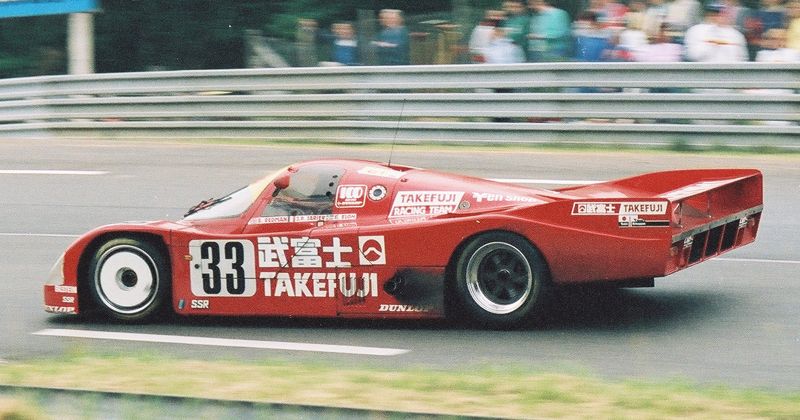

Phase PA – F1™ Phase CS – LE MANS

Phase CS – LE MANS Phase OR – Hypercar

Phase OR – Hypercar INCONEL

INCONEL CARBON FIBRE

CARBON FIBRE STAINLESS STEEL

STAINLESS STEEL TITANIUM

TITANIUM ALUMINIUM

ALUMINIUM THERMAL BARRIERS

THERMAL BARRIERS PRESS

PRESS CONTACTS

CONTACTS PHILOSOPHY

PHILOSOPHY